- by Wolf Tooth

Clipless Pedals: Engineering Precision

- by Wolf Tooth

We launched a new, improved B2B website for dealers, distributors, and OEM partners at b2b.wolftoothcomponents.com.

All accounts have been migrated to the new B2B website. Please bookmark the new website and log in with your previous account email to access B2B.

We are not able to refund your wholesale discount on orders placed through the consumer website.

Contact dealers@wolftoothcomponents.com with any questions.

The product development crew here at Wolf Tooth have a lot of miles on clipless pedals. Like really a lot – easily 200,000+ miles and 60+ years of cumulative riding experience. We have ridden clipless pedals in every possible condition, from the worst mud and snow to the driest and rockiest deserts, through a few thousand races and countless miles of singletrack and gravel. We have also ridden just about every binding system and pedal brand. When we started scoping our own clipless pedal project, one thing that became apparent was that no one was making the pedals we wanted to ride. Every other brand/design had compromises and was leaving important opportunities on the table. We set out to design and build the perfect clipless pedal family – something that would outperform every other clipless pedal in the areas that we found to be most important.

The first and perhaps easiest decision was going with an SPD-compatible binding/cleat. Many of the other systems work well, but none of them can match a properly designed SPD-compatible system for overall feel, reliability, and size/profile. It’s also hard to argue with the numbers; there are more riders with SPD cleats on their shoes than any other type. With so many other opportunities to improve, it wouldn’t make sense to invent yet another binding system just to be different. We wanted to make better pedals, not just different pedals.

We started this project over two years ago and have invested countless hours of design and testing time with dozens of different pedal body, binding, and cleat designs carefully tested and optimized both in the lab and on the trail. We even designed two custom test machines to enable us to compare and improve our binding system relative to other brands.

This realization sparked our mission: to design and build the perfect clipless pedal family, one that would consistently outperform all others in the areas we identified as most crucial. Clipless pedals needed a reboot.

CTRL_ALT_DEL_

At the start of this project, we identified these eight key factors in clipless pedal performance and invested a lot of time into understanding and optimizing each one. Some other clipless pedals are strong in a few of these areas, but only Wolf Tooth is a top performer in every single one.

Even more importantly, it gives you better control and confidence when riding. This really comes down to one thing: you need sufficient shoe lug contact with the pedal body.

Insufficient shoe lug contact also results in hot spots. This is common with shoes that have softer soles, but is also present even with stiff carbon soled shoes. Wolf Tooth clipless pedals strike the perfect balance of a connected feel but still maintain a low profile and easy clip-out performance.

ALT XC Clipless Pedal: Most XC pedal designs miss this entirely. On many pedals, the shoe lugs cannot even touch the pedal body, which prevents transfer of power because the metal cleat bottoms out on the metal binding parts too soon. On others, the surface area that the shoe lugs contact is too small to be of much help, so only a fraction of the potential power reaches the pedal body. The result is that most XC pedals feel like you are standing on a golf ball or at best, just not very stable or connected to the bike.

CTRL Trail Clipless Pedal: Some trail pedal manufacturers do a decent job of providing shoe lug contact, some do not, but most tend to be heavier and thicker than desired. Many still have way less contact area than they should, especially given their overall size. As with our XC pedal, we designed our trail pedal to provide the ideal level of shoe contact for softer trail shoes while maintaining a design that is super thin, lightweight, and compact. The Wolf Tooth ALT Trail Clipless Pedal has more shoe contact area (with a smaller overall size and weight) than any other trail pedal we know of.

DEL Gravel Race Clipless Pedal: Designed to provide a large shoe contact area with minimal weight and overall size. The single-sided design also allows better cornering clearance while keeping weight low. The pedaling feel is more like a road pedal but with excellent mud clearing and a walkable cleat/shoe. During prototype testing, our riders found these pedals to have all the benefits of road pedals with high power transfer, but are lighter and smaller.

A lot of this depends on the binding type. SPD systems tend to be some of the best, but there are a lot of little details that have to be understood and designed correctly for great performance – i.e. not all SPD-compatible designs feel great. We made numerous design iterations on the bindings and cleats to get this right. We even designed two special test machines to measure and compare clip-out performance. This allowed us to produce quantitative numbers to supplement our qualitative riding evaluations.

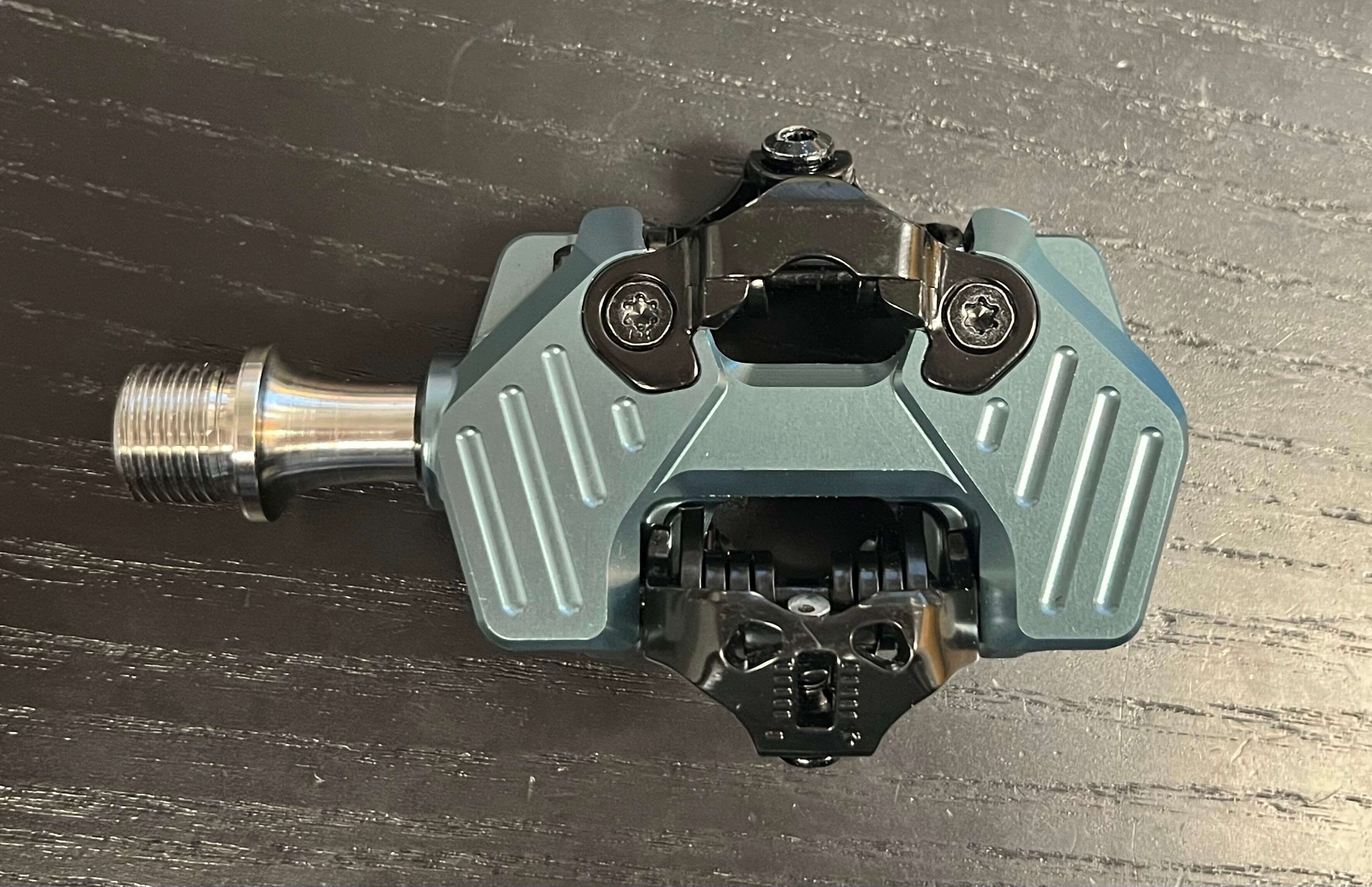

Thanks to a thin pedal body and thin binding mechanism. Clipless pedals tend to be used by riders who value maximum pedaling performance. Part of that is the ability to pedal when cornering or navigating trail obstacles like rocks and roots. The Wolf Tooth clipless pedal family has the thinnest and most compact bodies and binding mechanism to minimize pedal strikes and keep you moving through the toughest terrain. Our pedal bodies are 2-4 mm thinner than other designs.

There are few things more frustrating than having your pedal bearings fail in the middle of nowhere or having a design that is difficult to maintain and adjust. The Wolf Tooth clipless pedal family uses the proven and long-lasting design from our Waveform Aluminum Pedals with a system that includes three bearings, a custom igus bushing, and 17-4 PH stainless steel axle, but in a slightly more compact form.

When your pedals do eventually need service, it can be done quickly at home with a few simple tools. Our binding system is made from hardened stainless steel for rust resistance and strength. The stainless biding cages shrug off impacts from rocks and roots. If something does ever go wrong, replacement parts are available through our Right to Repair program.

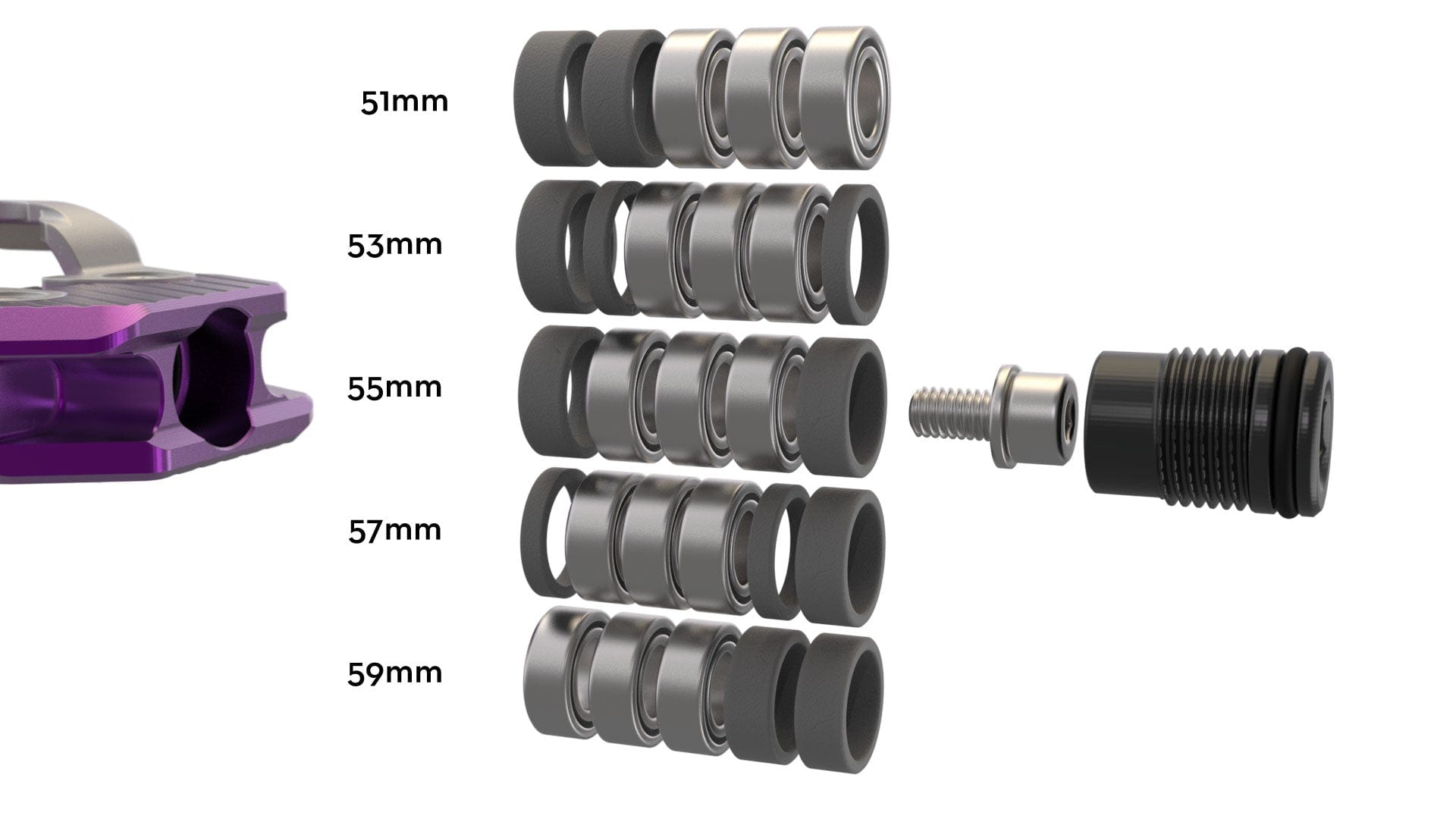

One size fits all usually means a compromise for all, but not here. In our quest to make the best possible pedal for as many riders as possible, we realized that a single Q factor is not perfect for everyone. Smaller riders might prefer a narrower pedal Q factor to offset the wider Q factor of modern MTB cranksets. This provides more cornering clearance and, for some, a better bike fit for more comfort and efficiency. Conversely, someone riding larger shoes (or bulky winter boots) might need a wider pedal Q factor to maintain best possible clip-out performance or to prevent shoes from rubbing the crank arms. Riders who split their time between MTB and gravel might find that setting their Wolf Tooth pedals to a wider Q factor on their gravel bike keeps their overall stance similar between the two bikes. This increases comfort and can reduce strain that can occur when your body is not acclimated to a bike fit change.

The full Wolf Tooth clipless pedal family can be set to widths of 51, 55 or 59 mm. A set of smaller 2 mm spacers are available as replacement parts to offer two more Q factor options of 53 and 57 mm. They are built with a default Q factor of 55 mm, which is similar to many other SPD-compatible pedals. The setting can be changed in about five minutes with nothing more than a couple hex keys. A video guide and instruction manual is provided on the Wolf Tooth website to walk you adjustment.

Nobody wants a heavy clipless pedal. We trimmed every last gram of unnecessary weight and relentlessly tested to make sure the pedals were still strong enough to put the Wolf Tooth name on them. Our pedals are the lightest weight available without compromising critical performance factors like shoe contact and clip in/out performance.

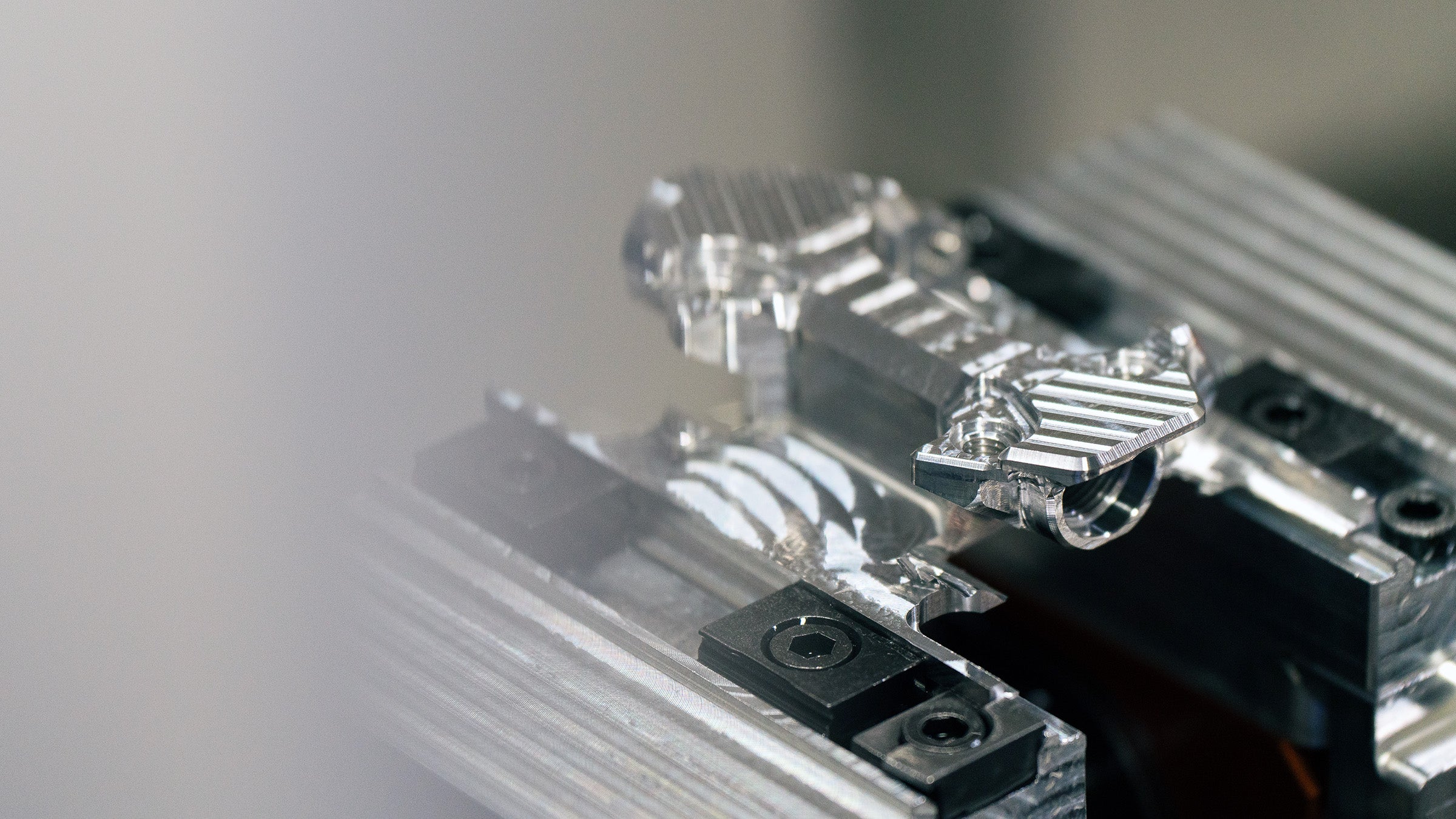

Perhaps not a top priority for every rider, but it’s important to us. We want our clipless pedals to look as great as they ride, so we spent a lot of extra time honing our designs to perfection and even trying many different CNC machining toolpath ideas to achieve the perfect Wolf Tooth CNC look. Of course they are also available in anodized colors to match the other Wolf Tooth components on your bike.

The Wolf Tooth clipless pedal family has narrower center axle housings than most other designs to allow mud and snow to push through. While every pedal can have issues in certain conditions, the Wolf Tooth pedals consistently perform better than others

The other half of the connection between pedals and shoes is shoes. Different shoes for different pedals. Some shoe brands/models perform much better than others on our pedals, just as they do with other brands of pedals. The two most important factors here are depth and width of the cleat pocket.

XC and gravel shoes are typically narrower and more minimal than a trail shoe. The outsoles are rigid plastic or carbon fiber for maximum power transfer. To work well with clipless pedals (from us or any other manufacturer), the shoes should have hard rubber lugs on either side of the cleat. The height of the lugs must be correct so that they can make good contact with the pedal body when clipped in. If the lugs are too short, whether from wear or a poor design, they will not contact the body. Instead, the steel cleat will contact the steel binding plates and make for a very poor pedal/shoe feel that is similar to standing on a golf ball.

Trail shoes are typically more flexible and have a larger, more walkable sole than their XC and gavel counterparts. Also, unlike XC/gravel shoes, the cleat pocket and lugs on trail shoes tend to have more variation between brands and models. Our pedals work well with all shoe brands and models we tested, and cleat shims are included to fine tune the shoe/pedal fit as needed.

Q factor adjustability is also important in connecting as many shoe types as possible with our new clipless pedals. We define Q factor with clipless pedals as the distance from the axle flange to the center of the binding mechanism. The most common distance for clipless pedals is 55 mm and this is also what we have chosen for the middle position of Wolf Tooth pedals. Unlike most other pedals, the CTRL + ALT + DEL family can be adjusted to 51 or 59 mm as well with the spacers built into the pedals. We also have a separate kit of 2 mm spacers available to add Q factor options of 53 and 57 mm.

There are two main reasons to adjust Q factor: shoe type/size and bike fit. One of the most common reasons for difficulty unclipping is due to interference between your shoe and the crank arm as you twist your foot to unclip. This is more common with trail shoes than with XC shoes due to the difference in shoe width and outsole design. To test, simply try unclipping while moving the crank arm into different positions. Definitely do this with your other foot on the ground. If you observe or feel any contact between your shoe and crank arm as you twist through the unclip point, you will likely benefit from changing to a wider pedal Q-factor setting like 55 or 59 mm. Sliding the cleat inboard on your shoe can also help for smaller adjustments.

Bike fit is another big reason to adjust Q factor. If you ride both a mountain bike and gravel bike, you may want to consider using a wider pedal Q factor on your gravel bike. This will provide a similar overall Q factor between bikes and will make switching between bikes more seamless. Some people may also just be more comfortable with a wider or narrower Q factor.

The result of years of development and countless miles of testing is a product line of clipless pedals unlike any other. We stressed over every detail. These three models are just the start.

CTRL + ALT + DEL

Dec 2023

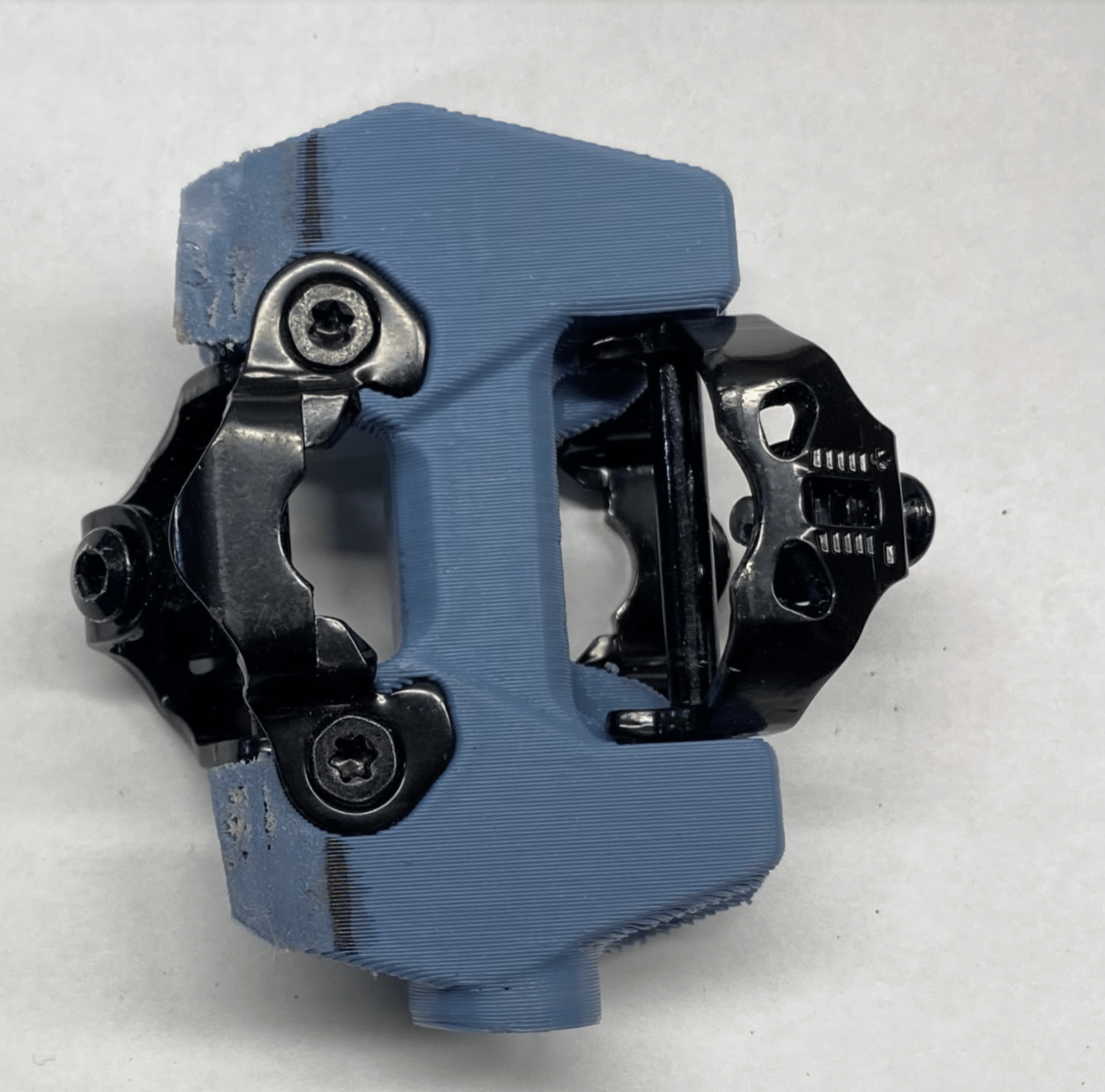

The first 3D Printed prototype pedal body was paired with salvaged clip in binding parts from a competitor pedal body to start working on pedal design architecture.

Jan - Jul 2024

Sweating the details. Refining platform surface area platform machining, body thickness, and axle / bearing configuration.

Aug 2024

Machined prototypes start to resemble what will become our final pedal design. Ride testing expands beyond the engineering and product teams.

Sep - Dec 2024

Ano samples are trickling in. The Move from 3D printed stainless steel bindings to stamped parts is a long iterative process until the feeling is just right.

Jan 2025

Our pedal body, cleat, and binding geometry has been dialed in, and production-ready prototypes are sent out to athletes and industry partners for final testing.

May 2025

Iterating through batch production to optimize tooling and machine paths to keep production time as low as possible.

Aug 2025

Production pedal bodies are back from anodizing, hit the laser machine, and are set up in assembly for batch building.

Sep 2025

Our assembly team was busy cranking out about 100 pairs of pedals per day while we were stocking up for our first distribution and key account pre-orders.

Oct 2025

CTRL + ALT + DEL

Launch day is finally here!

Chris Hall - Cycling The Perimeter Of Britain Documentary

No man is an island, entire of itself; Every man is a piece of the continent, a part of the main.

This feature-length film from Jack Hague and Chris Hall documents Chris' ride around the perimeter of Britain. A solitary epic, his ride was anything but. Showing how our sport, and our communities, can be a catalyst for healing.

The Toughest MTB Competition On Earth

Early this October, a crew of 30 freeriders, their dig teams, media, and fans descended on Virgin, Utah for the 19th edition, and 2nd annual women's competition, of Red Bull Rampage.

Share:

Orogenesis Dispatches: Part 2

The Toughest MTB Competition On Earth